China has sanctioned Boeing, Lockheed, and Raytheon over US arms sales to Taiwan

US Military and Arms Industries

Are Dependent on Chinese Components

David P. Goldman / Asia Times

(September 16, 2023) — Increased sanctions against China could leave the US economy vulnerable, especially in defense and basic infrastructure areas.

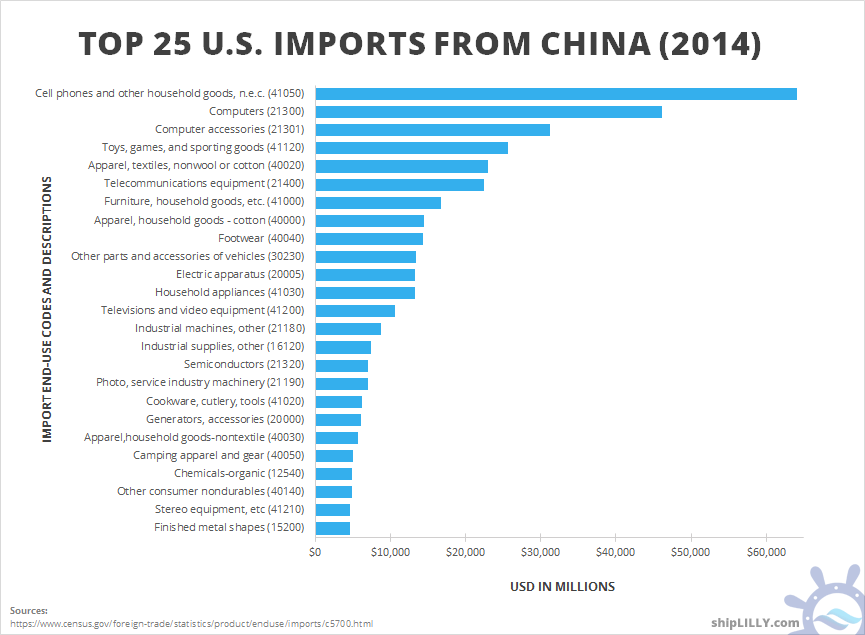

The US does not have the factories or skilled labor to replace Chinese imports. The US imported $33 billion in capital goods from China for electricity generation and distribution in 2022 — items no longer manufactured in the US. One of the country’s largest defense contractors, Raytheon, has several thousand suppliers in China and “disassociation” is impossible.

America doesn’t have the factories or skilled labor to replace Chinese imports that support defense contractors and basic infrastructure, leaving the US economy vulnerable to harm in the event of an all-out trade war with China, corporate and government officials told Asia Times.

That’s why Biden administration officials are unlikely to heed calls from China hawks to completely cut off China’s semiconductor sector from US technology.

A group of 10 prominent House Republicans wrote to the US Commerce Department on September 14 demanding a shutoff of US exports of chip technology to China, claiming that the export controls imposed in October 2022 were ineffective.

The Republicans’ letter cited “recent reports that Huawei Technologies Co. (Huawei) has developed a smartphone containing 7-nanometer (nm) chips, capable of supporting 5G, produced by the Chinese state-owned Semiconductor Manufacturing International Corp. (SMIC).”

“We are extremely troubled and perplexed about the Bureau of Industry and Security’s (BIS) inability to effectively write and enforce export control rules against violators, especially China,” the letter added.

US flags: Made in China.

Semianalysis.com, a prominent chip industry website, declared, “US sanctions have failed. It called Huawei’s 7-nanometer chip “technically incredible,” and “a better designed chip than most in the West realize,” with capabilities similar to Nvidia’s and Qualcomm’s best AI processers. It noted the chip was produced with high yields, “with no access to cutting edge US intellectual property, and intentionally hampered.”

Nothing short of a complete export ban on every category of semiconductor equipment would halt China’s progress, the website concluded. “Half measures will not work, but a full-scale assault will make it so the cost of replicating the semiconductor supply chain domestically is neigh on impossible. While we aren’t advocating for any of these specifically, it is clear the west can still stop China’s rise if decisive action is taken,” it wrote.

The US can’t stop China from making high-end chips like the new Kirin 9000 processor unless it shuts down all semiconductor fabrication in China. That would entail massive disruption not only of the semiconductor industry but of dozens of industries that depend on it, with grave economic consequences.

(Apologies for the expletives in this video presentation.)

It is far from clear that the US would be able to enlist allies like Japan, South Korea, and the Netherlands. The Biden administration gave into Korean demands to maintain their existing chip fabs in China.

Holland’s ASML, the leading maker of chip-making lithography machines, won’t sell its most advanced equipment to China, but continues to sell the Deep Ultraviolet (DUV) devices that SMIC used to make the new Huawei chip.

Even if the US could persuade other countries to join in a total boycott of chip-making equipment to China, the US is not the only country that can wage economic war. The disruptive impact on the world economy would be incalculable and one possible upshot would be paralysis in US critical infrastructure.

Public discussion about possible Chinese retaliation against additional US export controls has focused on a possible ban on the use of Apple handsets by Chinese government officials. However, American vulnerability is evident in the form of thousands of critical components used in critical infrastructure and the US defense industry.

The US imported US$33 billion in capital goods from China for electricity generation and distribution in 2022, items that are no longer manufactured in the US.

Substituting domestic production for these items would entail long lead times and exorbitant costs, industrial officials say. In the event of a full-scale trade war, a Chinese ban on critical components could cripple basic US infrastructure.

“The vulnerability of supply chains for critical infrastructure is acute and self-inflicted. The US and its allies have allowed themselves to become captive to Chinese cartels that control production of electronic components, high-powered magnets, printed circuit boards, computers, drones, rare earth metals, wind turbines, solar cells, cellular phones and lithium batteries… In fact, nearly every element of the technology-based digital smart grid is dependent on Chinese-made components,” Brien Sheahan, a former top US energy regulatory official, wrote in April.

US defense contractors also depend heavily on China. In a June 19 interview with the Financial Times, Raytheon CEO Greg Hayes said his company had “several thousand suppliers in China and decoupling is impossible. We can de-risk but not decouple,” adding that he believed this to be the case “for everybody” in US manufacturing.

Hayes added, “Think about the $500 billion of trade that goes from China to the US every year. More than 95% of rare earth materials or metals come from, or are processed in, China. There is no alternative. If we had to pull out of China, it would take us many, many years to re-establish that capability either domestically or in other friendly countries.”

Raytheon makes Tomahawk cruise missiles, Maverick air-to-surface missiles, Javelin anti-tank missiles and other mainstays of the American arsenal.

Meanwhile, American attempts at reducing dependence on foreign supply chains for critical goods have stalled. Taiwan’s TSMC, the world’s top chip fabricator, accepted $15 billion in cash subsidies and tax credits from the Biden administration to build a fab in Arizona, but shortages of skilled labor have delayed the plant until 2025.

The same bottlenecks would hamper US efforts to replace Chinese components in critical infrastructure. The US faces an air pocket in skilled labor supply during the next two years.

“The fact is that 22% of existing skilled manufacturing workers will be retiring by the end of 2025. This could result in as many as 2 million to 3.5 million unfilled manufacturing jobs by 2025,” according to the consulting firm HBK.

America’s capital stock of manufacturing equipment has remained stagnant since 2000, according to Federal Reserve calculations.

US orders for manufacturing equipment have been steady at between $1.5 billion and $2 billion a month, roughly half the level before the 2008 recession.

As the growth rate of manufacturing capital stock collapsed, America’s trade deficit surged.

_0.png)

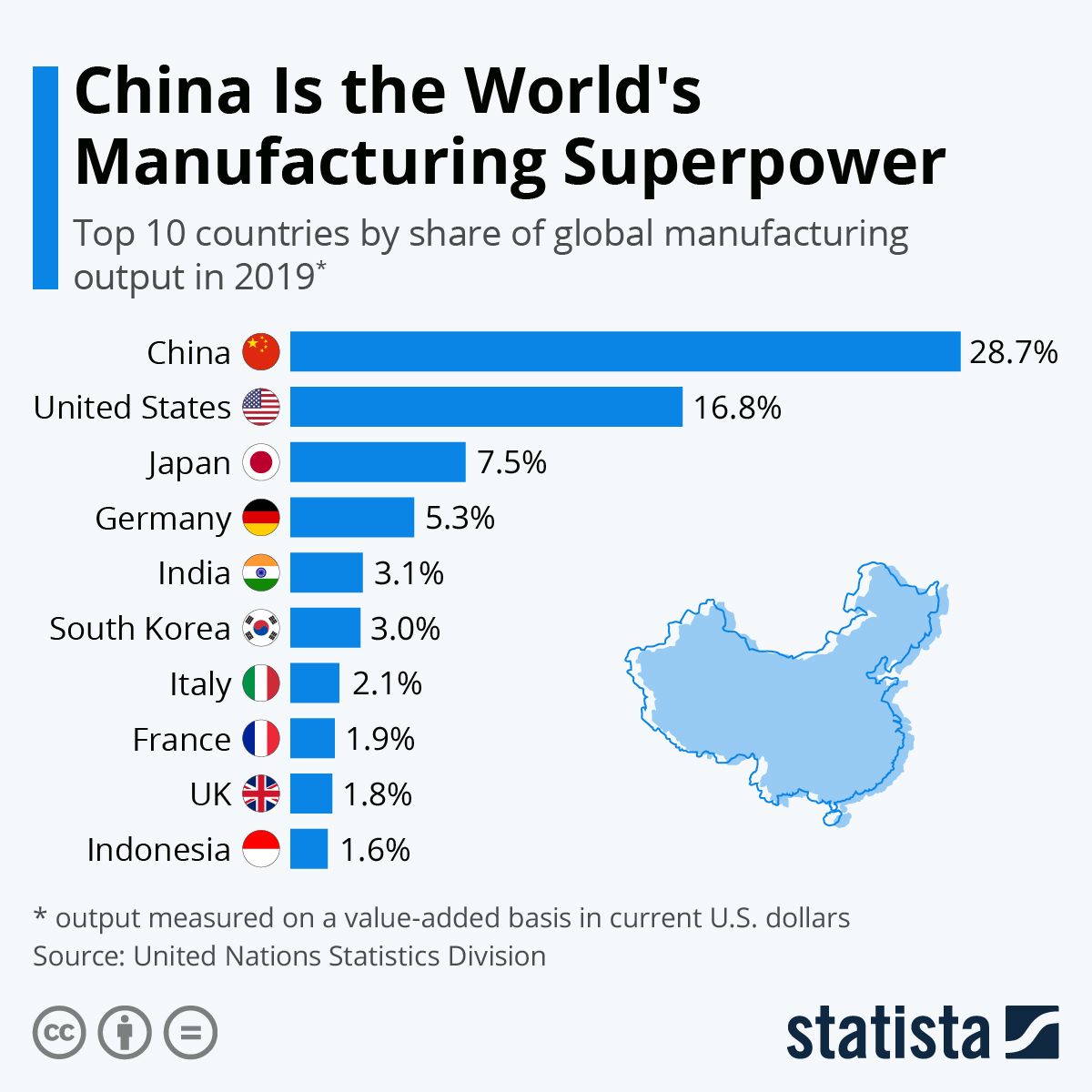

It’s true that China still depends on the West for a wide variety of chip-making equipment, while the US depends on China for a vast number of capital goods inputs. Both are capable of hurting each other badly.

The question is whether they will. Biden administration officials are keenly aware of American vulnerabilities, and reluctant to push the tech war against China to the point of Chinese retaliation.

Even with an all-out mobilization, it would take the US several years to build out sufficient flexible manufacturing capacity to replace critical Chinese components.

Follow David P Goldman on X, formerly Twitter, at @davidpgoldman

Posted in accordance with Title 17, Section 107, US Code, for noncommercial, educational purposes.